If you’re building a home or commercial building, the details of the concrete footings are easily overlooked until something goes wrong. Unfortunate, because the problems don’t arise until after its too late, and concrete footing design is one of the most important parts of any structure. Some say wisemen build on rock.

At Utah Screw Pile, we install deep foundations every day, and we’ve seen the good, the bad, and the ugly. We break footing design down into simple terms, give you a quick way to estimate footing sizes, and explain when it’s smart to consider helical piers instead. Often, replacing a simple spot footing can be done as easy as copy/paste.

What a Footing Does, and Why Concrete Footing Design Matters

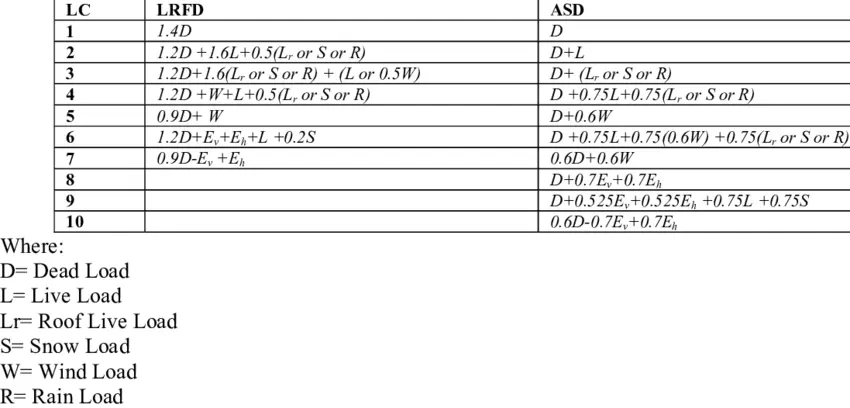

The role of your footing is simple: spread the weight of the structure over enough soil so anything built on it can be supported without settling, sinking or cracking under the weight. This weight includes the structure itself, the furniture and people inside, wind, seismic and even the snow and rain that may fall on the roof. Engineers have thought of everything! Below is a copy of Load Combinations.

A comparable example would be a snowshoe. A snowshoe spreads your weight, so you don’t sink. A footing does the same thing, but instead of keeping your body above snow, you’re keeping your house above the soil and ground water.

If your footing is too small for the soil beneath it, your structure will settle over time. Settling can be uniform; but more often it is uneven, leading to cracked foundations, sloped floors and crooked door jams.

Unfortunately, Utah’s soil is extremely mixed. Builders deal with:

- Dense and shallow bedrock of the Heber Valley and Park City

- Sandy loam in Utah County

- Soft clay in Saratoga Springs, Herriman and Vineyard

- Expansive clay along the valley benches

- Soft clay mixed with river rock near any current or historic river bed

Utahs divers soil characteristics are unique. In Utah, a thrown rock is said to touch 3 other soil profiles before coming to rest. For this reason, Utah is our beautiful home, but that means your footing size isn’t “one-size-fits-all.”

How Big Should a Footing Be?

Here’s a quick, homeowner-friendly table that shows what typical footing sizes should support. These are general, everyday values. These are good for decks, porches, small additions, and similar. Utah Screw Pile is not an engineering firm and should not be considered as such. The quality of the footing is dependent entirely on the subcontractor; factors like concrete compressive strength, rebar layout and size, as well as ground prep are all areas of zero compromise to meet these numbers.

| Footing Size, 12″ thick | Surface Area (Sq Ft) | Volume of Concrete (cu ft) | Approx Weight Supported |

| 12″x12″ | 1.0 | 1.0 | 1,000-1,500 lbs |

| 18″x18″ | 2.25 | 2.25 | 2,250-3,375 lbs |

| 24″x24″ | 4.0 | 4.0 | 4,000-6,000 lbs |

| 30″x30″ | 6.25 | 6.25 | 6,000-9,000 lbs |

| 36″x36″ | 9.0 | 9.0 | 9,000-13,500 lbs |

These are dimensions assuming some pretty safe variables of ground conditions (1,500 psf soil bearing pressure) and build quality, but for exact numbers, a geotechnical engineer and structural engineer should be consulted.

In contrast, a helical pier has load limits as well, but don’t rely on as many unknown factors like bearing pressure or concrete compressive strength. Helical piers require, zero excavation, no rebar, no concrete truck and zero ground prep. These screw piles are capable in almost every soil type and have zero surface disturbance. Below is a chart showing capacities of the standard CHANCE anchoring we install. Again, Utah Screw Pile and Helical Pier is not an engineering firm and should not be considered as such.

| Pier Shaft Size | Allowable Capacity | Uses |

| 1.5″ Square Shaft | 1,000-28,500 lbs | Standard size for small stand-alone footings and homes |

| 1.75″ Square Shaft | 10,000-52,500 lbs | Large capacity, commercial use and hard soil penetration |

| 2 7/8″ Round Shaft | 5,000-31,500 lbs | Great for suspended structures like walkways and decks that require lateral resistance |

| 3 1/2″ Round Shaft | 10,000-45,500 lbs | Large capacity, lateral resistance, design flexibility |

When using a helical pier, the actual capacity of the pier is known as soon as the quick installation is completed.

A Simple Way to Estimate Spot Footing Size

For those of us that need a quick answer for our basic brainstorms, a simple estimated weight could be considered when taking on your own concrete footing design. Some examples for getting a ballpark weight capacity are below:

- Deck post, no roof, no hot tub: 1,000-3,000 lbs

- Deck post, roof, no hot tub: 2,000-4,500 lbs

- Deck post, roof, hot tub: 5,000-10,000 lbs

- Small addition: 3,000-6,000 lbs

- Heavy beam or long span support: 6,000+ lbs

Every structure detail should be reviewed by an engineer, but this should help aim you in the right direction when considering your concrete footing design. When pricing a helical pier, please contact us to discuss an estimate and solution for your project.

When Concrete Footing Design Isn’t Enough

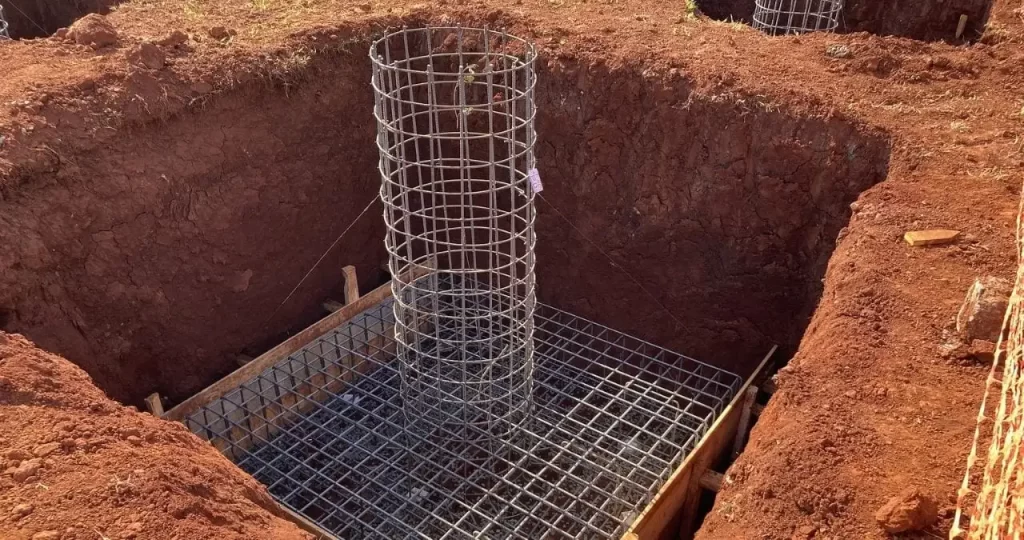

A perfect concrete footing design is just the start. Much is to be considered when building a footing that relies on the quality of the footings as well as the soil conditions such as:

- Is the excavation to virgin soil?

- What size is the rebar, how is it to be laid out, and is it tied together sufficiently?

- Is there sufficient compaction and gravel prior to pouring concrete?

- What is the slope of the installation location and how does that affect the stability?

- Does the soil in the area have a history of settling?

- How deep is the water table?

- Can this footing support future improvements and additional weight?

Each of these questions must be answered when pouring a footing. Each of these necessitates the need to hire a knowledgeable and competent builder with experience to foresee these possible issues. When building with a helical pier, very few have the same implications. Advantages of using a helical pier include:

- Quick installation, quicker than a 36″x36″ excavation

- No concrete trucks

- No excavation, or hauling soils offsite

- No forms, rebar, wire ties or visual inspections

- No J bolts to arrange in curing concrete, we build custom brackets and caps to your needs

- Little to no risk of settling

- Ability to build on immediately after installation, yes even before we are offsite!

- Simple inspection, often a pier installation report emailed to the city or inspector, included with every job we perform

If you’d like to consider these advantages, please give us a call, we would love to chat more: 801-900-3053